Description

MACHINE TYPE:

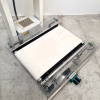

The checkweigher is designed for the continuous control of the weight of packages. The machine consists of two main structures: the weight detection system, which supports the weighing conveyor, and the system for diverting non-compliant packages. A feeding conveyor spaces the incoming packages evenly, while an output conveyor, located downstream of the weighing conveyor, is equipped with an ejection device that diverts out-of-tolerance and non-weighable packages from the line.

APPLICATION SECTOR:

Pharmaceutical, chemical, cosmetic, food, dietary, medical devices.

FEATURES:

The checkweigher can be integrated into a transport line for objects of any nature and shape. During passage over the checkweigher plate, the object takes a short time sufficient for the checkweigher to stabilize and detect the proportional weight of the object. After the weight reading, the packages pass onto the output conveyor, where the diversion system manages non-compliant packages. The machine operates independently of the downstream machine, and the speed of the conveyors is adjustable.

TECHNICAL SPECIFICATIONS

Overall dimensions (LxWxH) mm 1080x730x1550

Weight kg 100

Conveyor dimensions (LxW) mm 660×380

Conveyor height from the ground (min/max) mm 400/550

Capacity (max) Kg 220

Voltage / Frequency / Power V/Hz/kW 220/50/1.2

Year: 1998