Description

MACHINE TYPE:

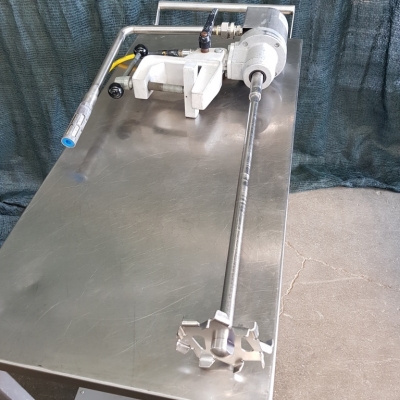

The Labor Pilot is a multifunctional machine for Research & Development with functions of agitation, mixing, homogenization, emulsification, suspension, and wet grinding, all combined in this new large compact machine.

APPLICATION SECTOR:

Pharmaceutical, chemical, cosmetic, food, dietary, medical devices.

FEATURES:

The basic device is a high-performance single-stage instrument for the continuous dispersion of liquids. The LABOR-PILOT is particularly suitable for scale-up to larger production machines, especially from the Inline 2000 series. The dispersing action is based on the rotor-stator principle, which means that a high-speed rotor with very narrow grooves rotates in a stator, producing high shear energies between the rotor and stator. The system consisting of rotor and stator is also called a generator. With the help of differently fine teeth, the device can be adapted to the respective dispersion task. With a standard three-phase alternating current, the motor drives the unit at 3000 rpm and protection class IP55. The transmission ratio of the belt drive increases the rotor shaft speed to 7900 rpm. The circumferential speed at the periphery of the rotor is approximately 23 m/s. Optionally, the speed of the LABOR-PILOT can be adjusted with the LABOR-PILOT CONTROLLER. The adjustable speed ranges from 3160 rpm to 13750 rpm. The maximum circumferential speed at the periphery of the rotor is about 40 m/s. As the circumferential speed of the rotor has a decisive influence on the dispersion result, the LABOR-PILOT CONTROLLER offers an excellent possibility to adapt the device to processing requirements.

TECHNICAL SPECIFICATIONS

Dimensions (LxWxH) mm 430x505x550

Power Supply 380 V 0.8 Kw 50/60 Hz

Manufacturer: Ika

Model: Labor Pilot 2000/4

Year: 2012